Feasibility check

Membrane filtration enables mixtures of substances to be separated, concentrated and purified. We recommend membrane screening or piloting if you do not know if membrane filtration can solve your problem. This can be done on a laboratory or pilot scale, by us or directly at your site. Naturally, we are there to assist you with your tests and to advise you.

Depending on your requirements, we can provide you with leased equipment in various sizes. Three example plants are presented briefly below.

The ideal test plant for investigating ceramic membranes using the cross-flow method. Due to its compact and robust design, the InoMini is optimal for laboratory tests and initial membrane suitability tests.

Filtration housing:

Quantity: 1 piece

Number of diaphragms per housing: 1 piece

Membrane geometry: Da = 10 mm, L = 500 mm

Technical data:

Max. Operating pressure: 40 bar

Max. Operating temperature: 60°C

Max. Overflow: 10 l/min

Power supply: 400 V, 50/60Hz, 1.5 kW

Mode of operation: manual

Data acquisition: manual

Dimensions: 940 x 660 x 850 mm

Weight: approx. 130kg

The ideal test plant for multichannel geometries on a laboratory scale. Due to its simple and compact design, it is ideally suited to perform initial suitability tests with one membrane as well as initial pilot tests with several parallel membranes. The unit can be disassembled into two parts for easier transport.

Filtration housing:

Quantity: 3 pieces (single as well as parallel operation possible)

Number of diaphragms per housing: 1 piece

Membrane geometry: Da = 25 mm, L = 1200 mm

Technical data:

Max. Operating pressure: 16 bar

Max. Operating temperature: 60°C

Max. Overflow: 10m³/h @ 1.5 bar

Power supply: 230 V, 16A 50/60Hz

Mode of operation: manual

Data acquisition: manual

Dimensions: 1200 x 600 x 1500 mm

Weight: approx. 250kg

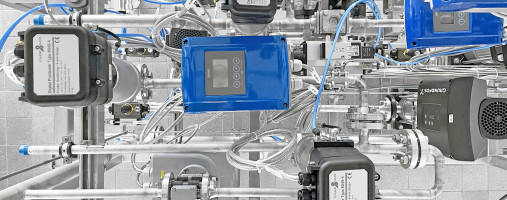

Pilot plant MF-1 "LISA" / NF-1 "DIVA"

The ideal plants for initial pilot tests at your site. Due to their flexible design, the plants can be adapted to a wide variety of applications. By testing different modes of operation, the best mode of operation for a production plant can be determined.

Filtration housing:

Quantity: 2 pieces in series

Number of diaphragms per housing: 3 pieces Da = 25mm, 1 piece Da = 41 mm

Membrane geometry: Da = 25 or 41 mm, L = 1200 mm

Technical data:

Max. Operating pressure: 16 or 24 bar

Max. Operating temperature: 80°C

Max. Overflow: 13m³/h @ 3 bar

Power supply: 400 V, 32A 50/60Hz

Mode of operation: automatic

Data acquisition/visualisation: automatic

Dimensions: 2800 x 1000 x 1900 mm

Weight: approx. 700kg

For more information and advice, please call us!

Our team is always ready to give you advice. Send us your enquiry or contact us by telephone.